India has firmly established itself as the second-largest producer and consumer of ceramic tiles globally, a remarkable position driven by a confluence of economic, demographic, and technological factors. The surging demand for ceramic and vitrified tiles has powered the success of every Ceramic Tiles Manufacturer in India, transforming the country's tile industry into a global powerhouse. Understanding this growth requires looking at the drivers that are reshaping India's construction and interior design landscape.

The Infrastructure and Urbanization Boom

The most significant driver of demand for any Tiles manufacturer in India is the nation's rapid urbanization and ambitious infrastructure development plans.

Real Estate Expansion: As millions migrate from rural to urban centres, the demand for both residential and commercial properties has exploded. Government initiatives like the "Housing for All" scheme and the "Smart Cities Mission" have fueled massive construction activity, creating a sustained need for durable, aesthetic, and affordable building materials like tiles.

Commercial & Public Projects: Tiles are no longer just for homes. Modern commercial spaces—from high-rise office complexes and retail malls to airports, hospitals, and metro stations—increasingly use vitrified and ceramic tiles for their superior durability and low-maintenance properties. This infrastructural growth provides a massive and non-stop revenue stream for the sector.

Rising Disposable Income and Aesthetic Preferences

A burgeoning middle class with higher disposable incomes is fundamentally changing consumer preferences, steering the market toward premium and designer tiles.

Aesthetic Appeal: Modern consumers are prioritizing the visual appeal and quality of their interiors. Tiles are seen as a long-term investment that elevates a property’s value and aesthetic. This shift drives demand for technologically advanced products, which Best Tiles manufacturers in India have readily adopted.

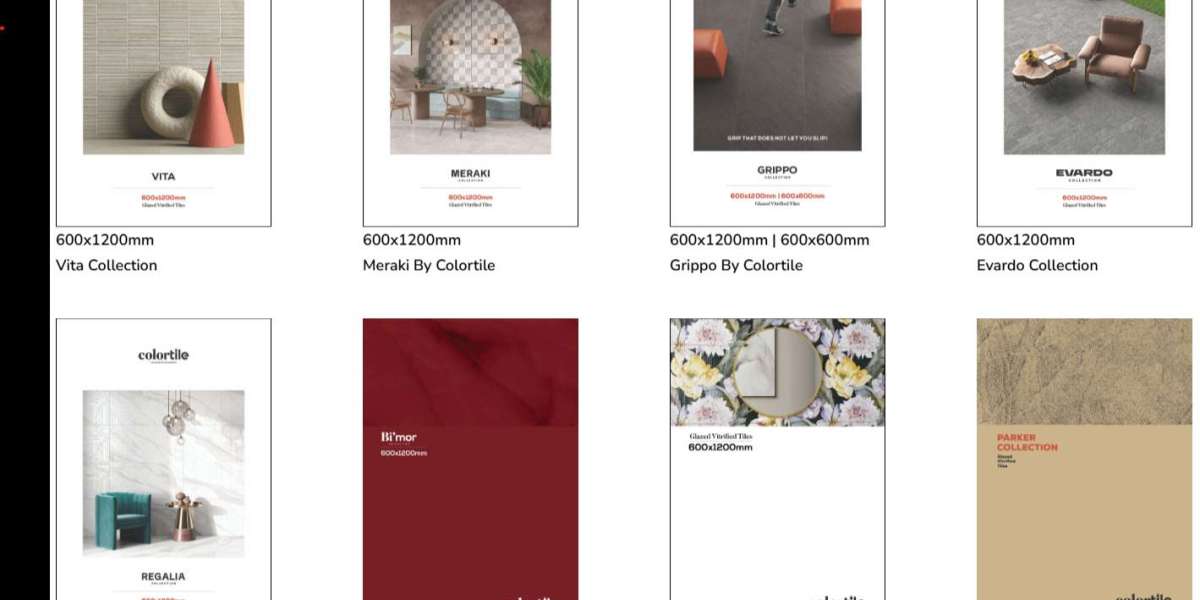

The Digital Revolution in Manufacturing: The use of high-definition digital printing technology has revolutionized design flexibility. Indian manufacturers can now produce tiles that flawlessly mimic natural materials like marble, wood, and stone, complete with intricate patterns and textures, but at a fraction of the cost and maintenance. This innovation allows consumers to achieve luxury looks affordably.

Focus on Hygiene and Renovation: Increased awareness of hygiene, especially post-pandemic, has made easy-to-clean, non-porous ceramic surfaces highly desirable. Furthermore, the renovation and replacement market, particularly in metro and Tier-1 cities, is growing fast, as homeowners upgrade older floors and walls with modern, premium tiles.

Global Competitiveness and Technological Edge

India’s dominance is not solely domestic; it is rooted in its growing global export capacity, particularly from manufacturing hubs like Morbi in Gujarat.

Quality and Affordability: Indian manufacturers have invested heavily in state-of-the-art European machinery, ensuring their products meet stringent international quality standards (like ISO and CE). This technological edge, combined with competitive manufacturing costs, allows the Ceramic Tiles Manufacturer in India to offer world-class quality at an attractive price point globally.

Product Innovation: The sector is constantly innovating, launching large-format slab tiles (which reduce grout lines and create a seamless look), along with specialized functional tiles such as anti-microbial, anti-skid, and full-body vitrified tiles. This focus on performance ensures the industry remains responsive to both domestic and international architectural demands.

In summary, the growing demand for the Tiles manufacturer in India is a potent combination of macroeconomic factors—urbanization and infrastructure—and microeconomic factors—rising consumer income and technological innovation. This robust foundation ensures the ceramic tile industry is poised for continued, aggressive growth for years to come.